User talk:Two OH five

Two OH five (Talk | contribs) |

Two OH five (Talk | contribs) |

||

| Line 149: | Line 149: | ||

And here's the sensor that actually picks up on that trigger wheel giving a high resolution crank angle sensor unlike the 12 tooth version in the stock ST205 distributor setup | And here's the sensor that actually picks up on that trigger wheel giving a high resolution crank angle sensor unlike the 12 tooth version in the stock ST205 distributor setup | ||

[img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1260.jpg[/img] | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1260.jpg[/img] | ||

| + | |||

| + | So it turns out that a 12mm shoulder drive socket fits the ARP-a-like rod nuts. It wasn't pleasant trying to unwind the first one even though the socket seemed to fit fine :lol: | ||

| + | |||

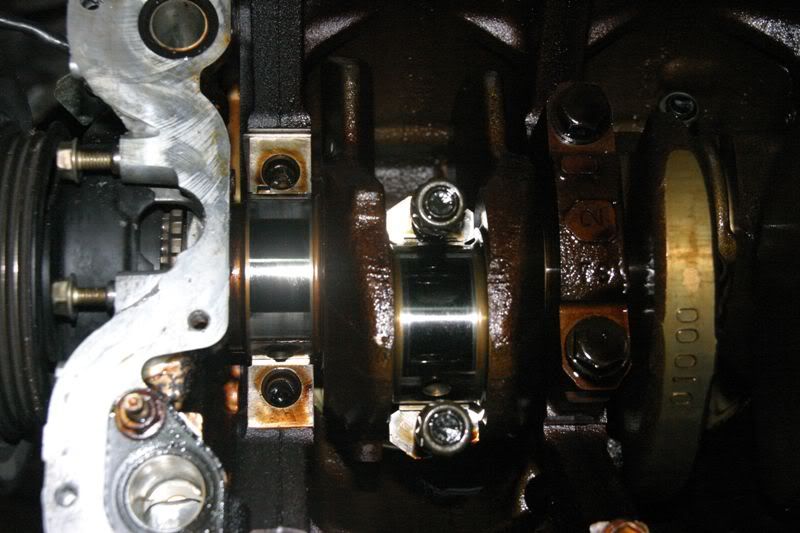

| + | No1 Main bearing and No1 Big end. Main bearing shows minimal wear, big end not showing too much either | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1262.jpg[/img] | ||

| + | |||

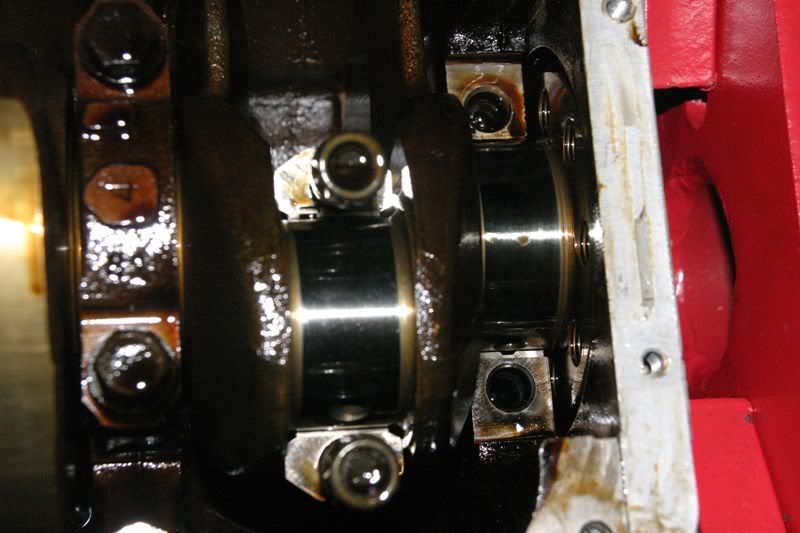

| + | Crank is shiney new but doesn't look it in the picture due to the oil on it | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1264.jpg[/img] | ||

| + | |||

| + | Number 5 main bearing and number 4 big end. The main doesn't even look broken in, big end shows some wear but not drastic | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1265.jpg[/img] | ||

| + | |||

| + | Again the crank journals look brand new under the oil | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1266.jpg[/img] | ||

| + | |||

| + | Number 2 main and big end. Again, little wear evident | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1268.jpg[/img] | ||

| + | |||

| + | Number 3 "central" main and number 3 big end. Being the super wide bearing the main looks brand new. Big end has minimal wear | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1269.jpg[/img] | ||

| + | |||

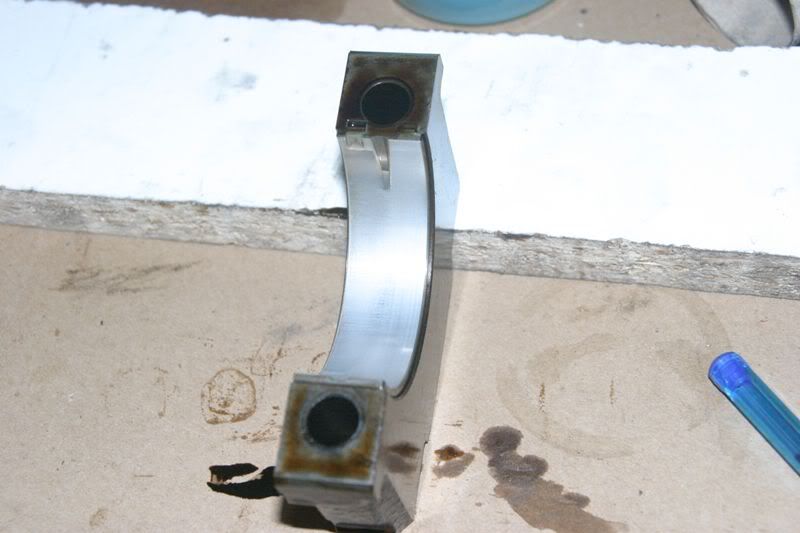

| + | The thrust bearings are the only set showing any real wear. Struck me as odd as the donk is from an auto so I expected less side thrust than a manual with clutch | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1270.jpg[/img] | ||

| + | |||

| + | Number 4 main, again looks brand new | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1271.jpg[/img] | ||

| + | |||

| + | Overall everything is showing very minimal wear. At this point I'm just going to order up a new set of original size bearings from Mr T and that will be that. There's nothing visible that makes me think the tolerances wont be as new this way | ||

| + | |||

| + | The block journals are 1 2 2 2 2 and the crank is 0 1 0 0 0 | ||

| + | Both pretty consistent. Original bearings, as expected, are 1 3 2 2 2 | ||

| + | |||

| + | Big ends are all size 2 | ||

| + | |||

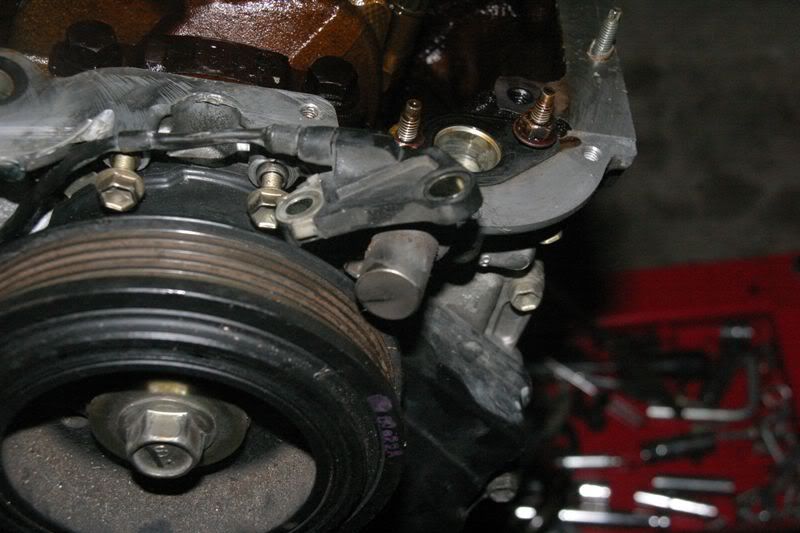

| + | Crank pulley removal. I forgot to photo the crank nut undoing procedure. A favourite method seems to be a block of wood thrown in the crankcase to wedge up the crank. Im not a huge fan of this. Instead I wound a couple of bolts into the flywheel drive plate and used the olf favourite crowbar between two bolts trick jamming the bar against the engine stand | ||

| + | Just for a laugh I decided to forgo the crowbar and twat it with a gurt hammer than so many people use to get the pulley off (judging by the number of chipped pulleys I've seen :( ). Instead I dug out a genuine puller. The crank pulley is conweniently provided with 2 bolt holes to allow this :) | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1267.jpg[/img] | ||

| + | |||

| + | Timing belt also looks brand new | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1272.jpg[/img] | ||

| + | |||

| + | Just for JP, part number 90919-05034 bolts on here like this | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1273.jpg[/img] | ||

| + | |||

| + | And picks up the trigger wheel shown more clearly here | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1277.jpg[/img] | ||

| + | |||

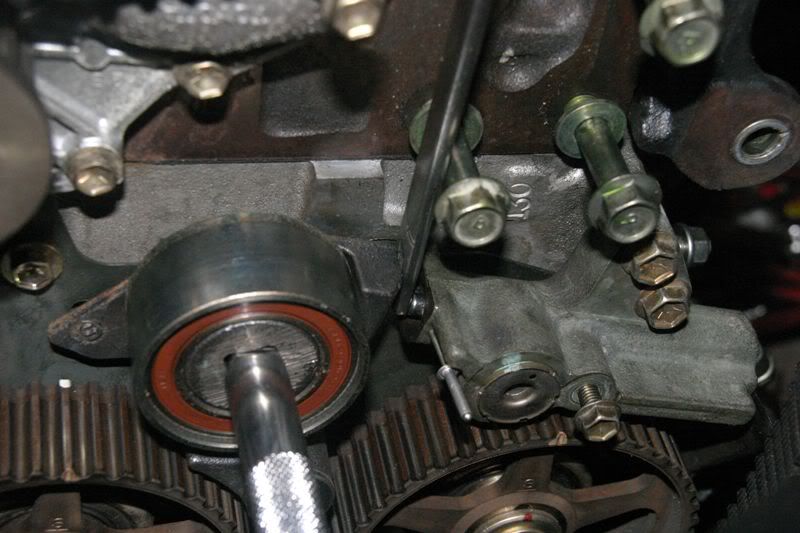

| + | Hey, that's handy. The 1/2" drive socket in the idler pulley means you can use a 1/2" drive ratchet (or torque wrench :lol: ) to slacken the tensioner enough to remove the belt | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1274.jpg[/img] | ||

| + | |||

| + | And with the aid of a thin bar you can actually reset the tensioner and insert the pin without resorting to stuff in vices. | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1275.jpg[/img] | ||

| + | |||

| + | One thing to remember.......Undo the oil pump pulley before removing before removing the cambelt. Otherwise, re-assembley is the reverse procedure to get the belt back on | ||

| + | |||

| + | |||

| + | Water pump removed. Yawn, it looks almost new although there is a tiny bit of float in the bearing | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1276.jpg[/img] | ||

| + | |||

| + | Oil pressure relief valve. Minor varnishing but predictably otherwise new looking | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1278.jpg[/img] | ||

| + | |||

| + | Project for tomorrow. This head needs to be stripped ready to be dropped off with the man who'se going to give it once over for me. It'll be getting new stem seals for sure and guides and a skim if needs be (assuming it's not scrap lol) | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1279.jpg[/img] | ||

| + | |||

| + | |||

| + | So, overall sitrep..... | ||

| + | I do genuinely believe that this is a low mile engine as advertised. Given that it's off eGay I didn't necessarily expect this. I could have pretty much plonked it in without anything to worry about on the bearing front. Still need to whip the head off and check the pistons but I'm hopeful they'll be OK | ||

| + | |||

| + | As it is it will get new bearings all round, new oil and water pumps, pressure regulator, cambelt, idlers etc etc Even though it doesn't really seem to need them it would seem daft to me not to replace all this stuff. The engine should hopefully then be tool free until the next cambelt service is needed | ||

| + | |||

| + | BAH, | ||

| + | |||

| + | Spent hours looking for valve spring compressors, various other tools and the box of ziplock bags I bought ages ago. Unsuccessfully :( | ||

| + | |||

| + | So, back to good old catch it a gurt smite with 'ammer methods then :lol: | ||

| + | Skip the next photo if you're feint hearted | ||

| + | Once you've removed the bucket the spring seat and collets are looking at you (the shim sticks to the magnetic bucket ;) ). Place a 19-20mm socket on the spring seat and........... SWING (not too hard, start reasonably gently) | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1281.jpg[/img] | ||

| + | |||

| + | If all goes to plan the collets will jump out of the valve grooves and the springs are released, leaving you with the bits below. The socket should contain all the flying bits. If all doesn't go to plan you'll either have a black thumbnail or there's a valve spring embedded in the roof and the collets have flown south for the winter :roll: | ||

| + | Note the labelled bag. This is #8 exhaust valve bits and they all stay together. | ||

| + | Inlet springs are marked with red paint, exhaust with green and the painted end goes into the bucket | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1282.jpg[/img] | ||

| + | |||

| + | Spring, spring seat and shim assembled as they would be in the head | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1284.jpg[/img] | ||

| + | |||

| + | As above but with the bucket in place | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1285.jpg[/img] | ||

| + | |||

| + | The whole Valve "stack" as it would be in the head | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1286.jpg[/img] | ||

| + | |||

| + | Once all the gubbins is removed you're looking at the valve stem seal. Apparently a bit of a pain to remove without the right tools. So I didn't try :D | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1287.jpg[/img] | ||

| + | |||

| + | Valves themselves are all in pretty good nick | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1288.jpg[/img] | ||

| + | |||

| + | Not much coke either | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1289.jpg[/img] | ||

| + | |||

| + | My calibrated Wicks T square shows the head is reasonably flat but it won't actually span the entire face :lol: | ||

| + | It will get a skim if required | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1291.jpg[/img] | ||

| + | |||

| + | I'm mad at mtself for this. When I bought the head a couple of years ago I checked it over and found everything acceptable. Apparently I failed to notice the two snapped exhaust studs in the middle then :oops: Thanks GTSChris :evil: | ||

| + | I'm reliably informed that this can be dealt with no problem | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1292.jpg[/img] | ||

| + | |||

| + | Nicely wrapped up and ready for delivery to my local head refurb expert | ||

| + | [img]http://i21.photobucket.com/albums/b277/Stevo_st205/Caldina%20Engine%20Rebuild/IMG_1294.jpg[/img] | ||

Revision as of 23:10, 16 August 2011

ST215 Caldina Engine Rebuild

OK, here's the plan

The engine in Black Beauty is tired and suffering big end rattle

I want to go aftermarket ECU with coil on plug in Hannibal with a sidefeed manifold

The solution is obvious to me

First buy one of these. It's apparently a low mileage ST215 caldina engine bought og fLeabay. Hmmmmmmmm

The idea is to refresh this bottom end with new bearings, pumps, pressure relief valves etc etc. It will then go into Black Beauty which will revert to standard ECU running notionally stock power as my reliable daily driver The good bits will then be transferred onto my current forged block

Along the way I'll try to detail a few things and probably bore everyone to photographic death :lol:

An interesting feature. The ST215 uses a turbo that looks similar on the compressor side to a CT20 ST205 turbo. The hotside is obviously a little different! It's an integrated hotside/manifold setup

For reference, a 205 WRC manifold plonked on top. You can see that the lineup is about the same as the 205 setup position wise

[img] [/img]

[/img]

Mmmmmm sidefeed manifold and coil on plug goodness :D :D

[img] [/img]

[/img]

There's two things to note here. There's a distinct lack of even a vestigial dizzy. Ant the water elbow only has one sensor. No more ECU + dash sensor setup

[img] [/img]

[/img]

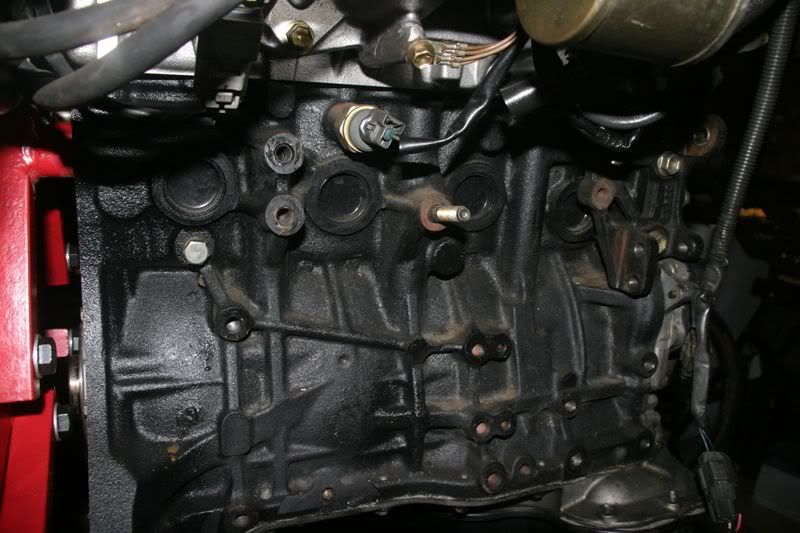

Round the back it's immediately obvious the knock sensor has moved

Also note the shiney bolt middle left. This goes directly into the water jacket. I can't remember if the 205 block has such a drain or not

[img] [/img]

[/img]

Top mount intercooler. Significantly better than the 185 setup, bigger and thicker. Also equipped with plastic tanks

[img] [/img]

[/img]

Front of the engine looks familiar. Note that the cambelt tensioner pulley is different with a 1/2" square drive in the centre for some reason

[img] [/img]

[/img]

Turbo support bracket is a much more sensible steel affair compared to the ST205 braacket which is hewn from solid heavy

[img] [/img]

[/img]

Doughnut oil cooler is redesigned but still present on the 215. On the ST245 caldina it's gone!

[img] [/img]

[/img]

The sensor in the middle is the TPS (Turbo Pressure sensor) which is now directly bolted to the manifold not the firewall

[img] [/img]

[/img]

Where the dizzy would normally be is now the location for the turbo VSV control unit

[img] [/img]

[/img]

Which is also attached to this resevoir on the rear of the manifold. Presumably this provides a smooth pressure despite the PWM action of the VSV controller

[img] [/img]

[/img]

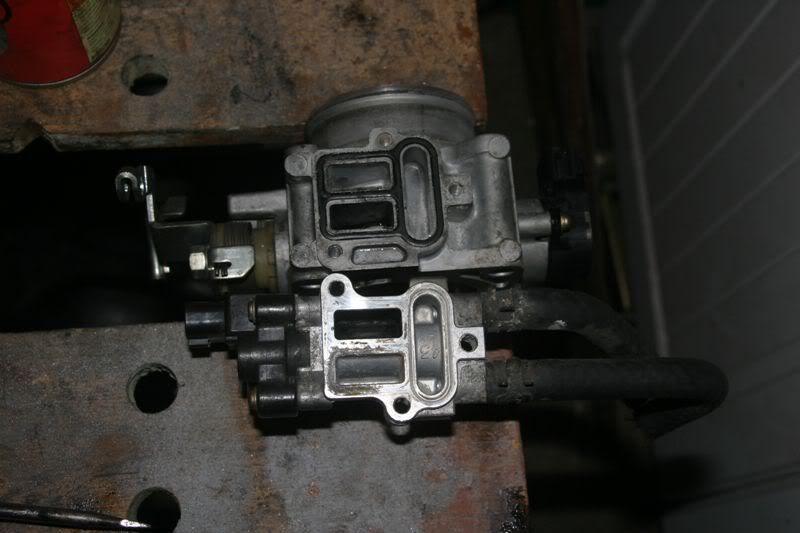

Front of the throttle body. Note the ISC attached to the bottom. It appears to be the same as that used on the 205 complete with throttlebody heating circuit

[img] [/img]

[/img]

Rear of the throttlebody. Not dissimilat to the 205 unit

[img] [/img]

[/img]

Disassembled IAC control block. You can see the barrel "throttle" of the ISC and you can also see that the manifold heater is just a very short direct connection channel. It does not go round the TB in any way

[img] [/img]

[/img]

4 layer exhaust manifold gasket is made up of 4 single identical steel gaskets

[img] [/img]

[/img]

Head exhaust ports and stud pattern appear identical to a st205 head

[img] [/img]

[/img]

Note the change to a "log" manifold. On the 205 manifold there's some separation of exhaust to make the twin scroll turbo work. On the 215 all the exhaust ports are conected into a single pipe. I'm certain this means no twin scroll

[img] [/img]

[/img]

Once the turbo VSV resevoir has been removed another VSV is immediately visible....more later

[img] [/img]

[img]

[/img]

[img] [/img]

[/img]

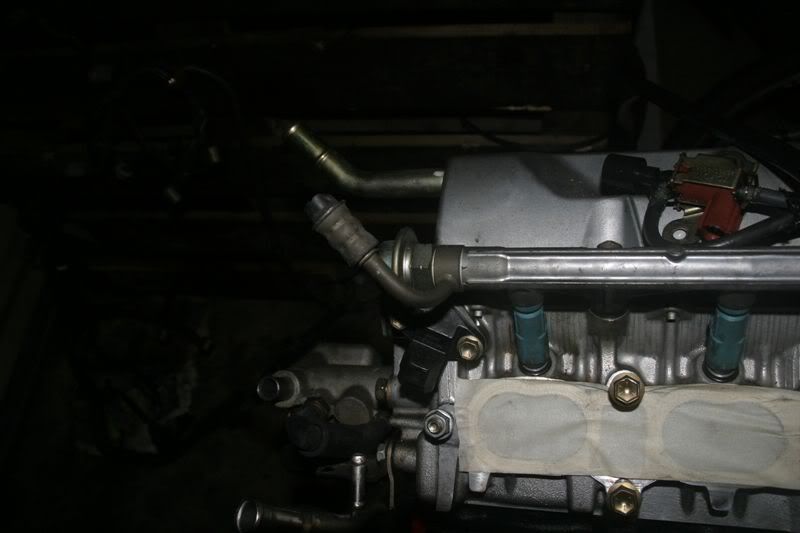

Off with the inlet manifold then. You can clearly see that the 215 has switched back to top feed injectors a la ST165

[img] [/img]

[/img]

Fuel return and FPR

[img] [/img]

[/img]

Fuel feed

[img] [/img]

[/img]

The rail is perfectly set up for a fuel pressure gauge. The large nut undet the FPR is removable and directly accesses the fuel rail :D

[img] [/img]

[/img]

With everything out of the way you can now see that the FPR is connected to the VSV that was on the back of the inlet manifold. I assume this does away with the fuel pump resistor but I don't know for sure

[img] [/img]

[/img]

It's a bit of a poor photo but you can actually see right through the fuel rail if you look hard. Internal Diam of the fuel rail is ~10mm. It's a pretty good looking rail for high power

[img] [/img]

[/img]

Coil on plug packs :D :D

[img] [/img]

[/img]

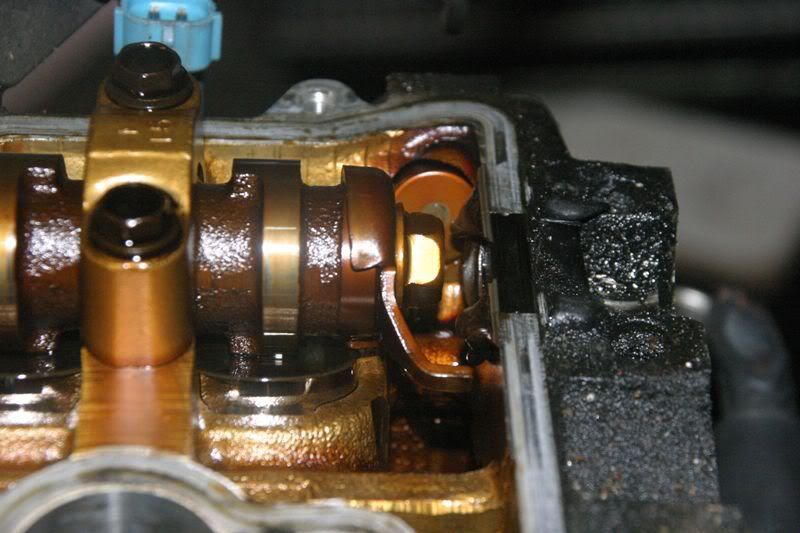

A vital part of the coil on plug setup. With no dizzy you need another cam position sensor. This is it and it's great news for me :D. The "trigger wheel" is attached to the end of the inlet camshaft. You can also see the sensor in the background

[img] [/img]

The cam sensor is simply bolted on in place of the dizzy. This means the nice 264 cams in Hannibal should work fine with the system (they might need a bolt hole drilling but that's apparently it)

You can also see the blank used to dispense with the dizzy shaft. This one is clearly well sealed then :roll:

[img]

[/img]

The cam sensor is simply bolted on in place of the dizzy. This means the nice 264 cams in Hannibal should work fine with the system (they might need a bolt hole drilling but that's apparently it)

You can also see the blank used to dispense with the dizzy shaft. This one is clearly well sealed then :roll:

[img] [/img]

[/img]

The buckets show no visible wear. I think this might be a genuine low mileage engine :shock:

[img] [/img]

[/img]

Nothing unusual here except....The cam cover has an inbuilt catch can type setup. The baffle plate should condense any oil out

[img] [/img]

[/img]

And the view from abovu. Note lugs to secure the COP units and a return to a 185 style breather position

[img] [/img]

[/img]

Better view of the distributor replacement plug with several feet of leaky crud removed

[img] [/img]

[/img]

Gratuitous photo of things to come for Hannibal. GT3071 with (eventually) external remote wastegate :twisted:

I'd really really like to turn the turbo the other way up though ;)

[img] [/img]

[/img]

A few closeups of the combined mani/turbo setup. Note the hulking great single wastegate. Boost creep should not be an issue on the Caldina :D

[img] [/img]

[img]

[/img]

[img] [/img]

[img]

[/img]

[img] [/img]

[/img]

And over we go :lol:

After an hour of unsuccessful panning for gold in the metal sump, off with the main sump section. Nothing bad looking here. The usual 3S-GTE varnishing but nowt unusual. This really might be a low miler. Time will tell

I wonder if my warranty is still valid :lol:

[img] [/img]

[/img]

Scraper plate removed and block face cleaned ready for a nice new bead of sealant. Nothing looks out of place or different here

[img] [/img]

[/img]

A poor picture but you can just about make out the oil squirter underneath the counterweight

[img] [/img]

[/img]

- lol:I hope you're reading this Don :lol:

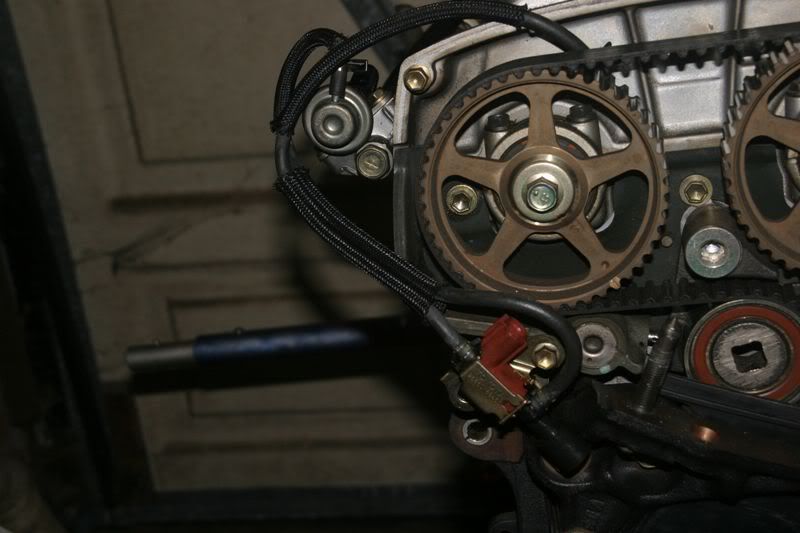

Part 2 of the COP setup. You can see a crank trigger wheel built into the cambelt drive puley

[img] [/img]

[/img]

And here's the sensor that actually picks up on that trigger wheel giving a high resolution crank angle sensor unlike the 12 tooth version in the stock ST205 distributor setup

[img] [/img]

[/img]

So it turns out that a 12mm shoulder drive socket fits the ARP-a-like rod nuts. It wasn't pleasant trying to unwind the first one even though the socket seemed to fit fine :lol:

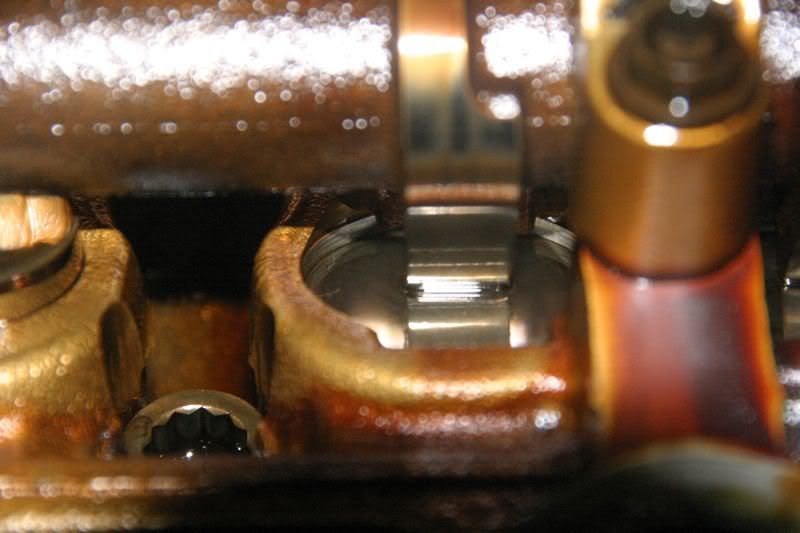

No1 Main bearing and No1 Big end. Main bearing shows minimal wear, big end not showing too much either

[img] [/img]

[/img]

Crank is shiney new but doesn't look it in the picture due to the oil on it

[img] [/img]

[/img]

Number 5 main bearing and number 4 big end. The main doesn't even look broken in, big end shows some wear but not drastic

[img] [/img]

[/img]

Again the crank journals look brand new under the oil

[img] [/img]

[/img]

Number 2 main and big end. Again, little wear evident

[img] [/img]

[/img]

Number 3 "central" main and number 3 big end. Being the super wide bearing the main looks brand new. Big end has minimal wear

[img] [/img]

[/img]

The thrust bearings are the only set showing any real wear. Struck me as odd as the donk is from an auto so I expected less side thrust than a manual with clutch

[img] [/img]

[/img]

Number 4 main, again looks brand new

[img] [/img]

[/img]

Overall everything is showing very minimal wear. At this point I'm just going to order up a new set of original size bearings from Mr T and that will be that. There's nothing visible that makes me think the tolerances wont be as new this way

The block journals are 1 2 2 2 2 and the crank is 0 1 0 0 0 Both pretty consistent. Original bearings, as expected, are 1 3 2 2 2

Big ends are all size 2

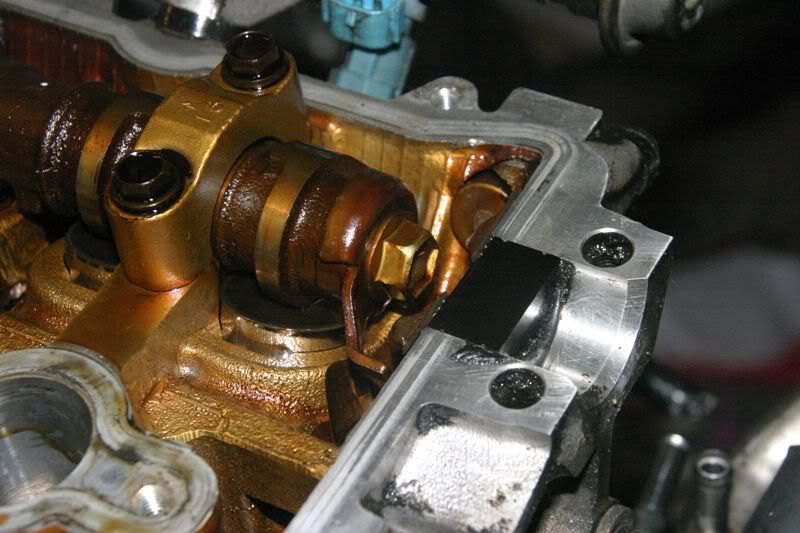

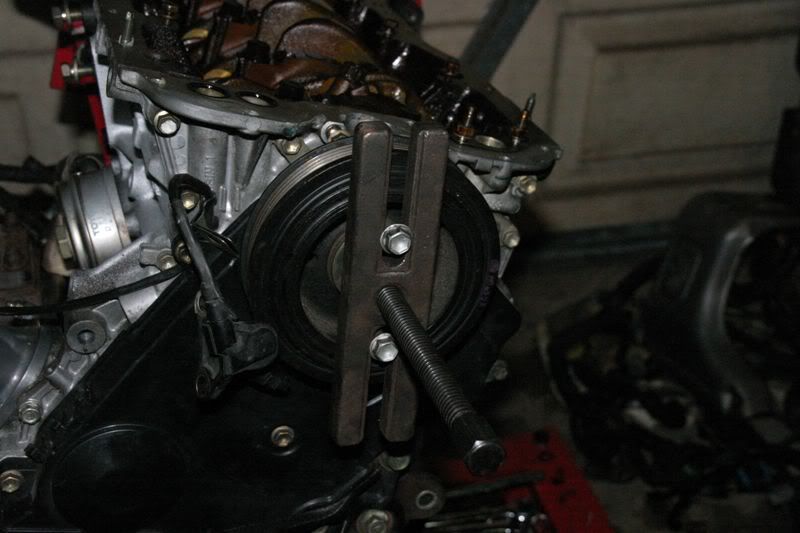

Crank pulley removal. I forgot to photo the crank nut undoing procedure. A favourite method seems to be a block of wood thrown in the crankcase to wedge up the crank. Im not a huge fan of this. Instead I wound a couple of bolts into the flywheel drive plate and used the olf favourite crowbar between two bolts trick jamming the bar against the engine stand

Just for a laugh I decided to forgo the crowbar and twat it with a gurt hammer than so many people use to get the pulley off (judging by the number of chipped pulleys I've seen :( ). Instead I dug out a genuine puller. The crank pulley is conweniently provided with 2 bolt holes to allow this :)

[img] [/img]

[/img]

Timing belt also looks brand new

[img] [/img]

[/img]

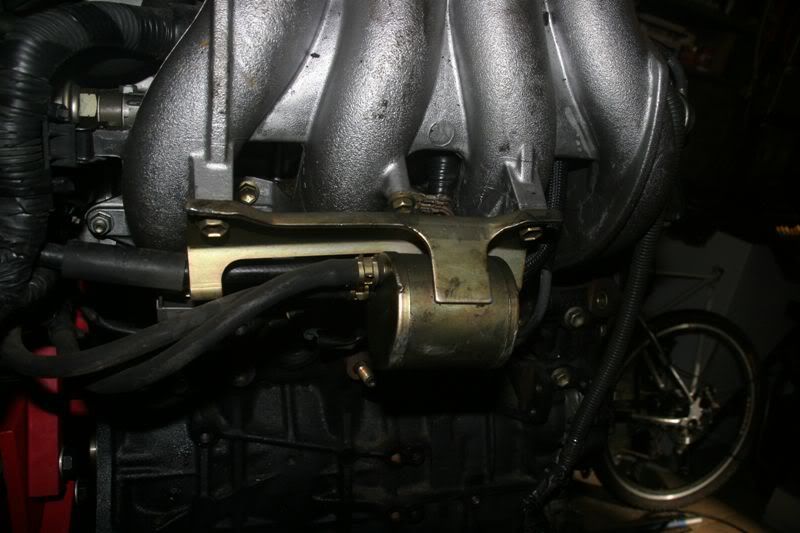

Just for JP, part number 90919-05034 bolts on here like this

[img] [/img]

[/img]

And picks up the trigger wheel shown more clearly here

[img] [/img]

[/img]

Hey, that's handy. The 1/2" drive socket in the idler pulley means you can use a 1/2" drive ratchet (or torque wrench :lol: ) to slacken the tensioner enough to remove the belt

[img] [/img]

[/img]

And with the aid of a thin bar you can actually reset the tensioner and insert the pin without resorting to stuff in vices.

[img] [/img]

[/img]

One thing to remember.......Undo the oil pump pulley before removing before removing the cambelt. Otherwise, re-assembley is the reverse procedure to get the belt back on

Water pump removed. Yawn, it looks almost new although there is a tiny bit of float in the bearing

[img] [/img]

[/img]

Oil pressure relief valve. Minor varnishing but predictably otherwise new looking

[img] [/img]

[/img]

Project for tomorrow. This head needs to be stripped ready to be dropped off with the man who'se going to give it once over for me. It'll be getting new stem seals for sure and guides and a skim if needs be (assuming it's not scrap lol)

[img] [/img]

[/img]

So, overall sitrep.....

I do genuinely believe that this is a low mile engine as advertised. Given that it's off eGay I didn't necessarily expect this. I could have pretty much plonked it in without anything to worry about on the bearing front. Still need to whip the head off and check the pistons but I'm hopeful they'll be OK

As it is it will get new bearings all round, new oil and water pumps, pressure regulator, cambelt, idlers etc etc Even though it doesn't really seem to need them it would seem daft to me not to replace all this stuff. The engine should hopefully then be tool free until the next cambelt service is needed

BAH,

Spent hours looking for valve spring compressors, various other tools and the box of ziplock bags I bought ages ago. Unsuccessfully :(

So, back to good old catch it a gurt smite with 'ammer methods then :lol:

Skip the next photo if you're feint hearted

Once you've removed the bucket the spring seat and collets are looking at you (the shim sticks to the magnetic bucket ;) ). Place a 19-20mm socket on the spring seat and........... SWING (not too hard, start reasonably gently)

[img] [/img]

[/img]

If all goes to plan the collets will jump out of the valve grooves and the springs are released, leaving you with the bits below. The socket should contain all the flying bits. If all doesn't go to plan you'll either have a black thumbnail or there's a valve spring embedded in the roof and the collets have flown south for the winter :roll:

Note the labelled bag. This is #8 exhaust valve bits and they all stay together.

Inlet springs are marked with red paint, exhaust with green and the painted end goes into the bucket

[img] [/img]

[/img]

Spring, spring seat and shim assembled as they would be in the head

[img] [/img]

[/img]

As above but with the bucket in place

[img] [/img]

[/img]

The whole Valve "stack" as it would be in the head

[img] [/img]

[/img]

Once all the gubbins is removed you're looking at the valve stem seal. Apparently a bit of a pain to remove without the right tools. So I didn't try :D

[img] [/img]

[/img]

Valves themselves are all in pretty good nick

[img] [/img]

[/img]

Not much coke either

[img] [/img]

[/img]

My calibrated Wicks T square shows the head is reasonably flat but it won't actually span the entire face :lol:

It will get a skim if required

[img] [/img]

[/img]

I'm mad at mtself for this. When I bought the head a couple of years ago I checked it over and found everything acceptable. Apparently I failed to notice the two snapped exhaust studs in the middle then :oops: Thanks GTSChris :evil:

I'm reliably informed that this can be dealt with no problem

[img] [/img]

[/img]

Nicely wrapped up and ready for delivery to my local head refurb expert

[img] [/img]

[/img]